News Release

Japan Agricultural Cooperatives Produce High Quality Soybeans in Tomamae-cho

May 10, 2011

May 10, 2011

Japan Agricultural Cooperatives Produce High Quality Soybeans in Tomamae-cho

New Beans Drying and Conditioning Facility Delivers Significant Quality Improvements

JA Tomamae built a new bean drying and conditioning facility in 2009. The new facility allowed them to expand production and improve the quality of the soybeans they produced.

|

| Yukihiro Matsubara, representative director of JA Tomamae-cho |

|

| Hiroshi Nendai, manager in the economic section |

|

| Akira Maekawa, subsection chief in the farming section |

Pride in Agricultural Products

JA Tomamae-cho was established in February, 1948 and specializes in rice, vegetables, dairy products and upland farming. JA Tomamae-cho cultivates approximately 3,600 ha, including 1,750 ha of rice fields.About 70 % of the rice produced in Tomamae-cho is "Nanatsuboshi". This variety, which has a low protein value and lustrous surface, is well-suited to the climate in Tomamae-cho. Outside of rice, the main agricultural products of the region are melon, mini tomatoes, pumpkin and corn.

Yukihiro Matsubara, representative director, states that Tomamae-cho supplies 3 % of yield and 100 % does not achieve without Tomamae-cho. This sentence demonstrates Mr. Matsubara’s pride in producing high quality agricultural products, not simply in producing a large amount. JA Tomamae-cho promotes the sharing of facilities and machinery to help farmers reduce costs, as well as joint business ventures and farm land intensification. In addition, JA Tomamae-cho facilitates a labeling system designed by Hokkaido Clean Agriculture Organization to promote cultivation that use reduced amounts of fertilizer. Tomamae-cho is well known for agricultural production in Hokkaido. Furthermore, they have formed a special cultivation contract with their customers, where they refrain from using powdery pesticides (DL pesticide included) to prevent pesticide dispersion. They are also committed to creating and maintaining good soil through the use of high quality compost received from nearby dairy farmers.

Increasing Soybean Production

JA Tomamae-cho is also concentrating on soybean production. About 96 % of the domestic consumption of soybeans is imported. Many customers do not want genetically modified agricultural products. Demand for domestic soybeans is increasing to the extent that soybeans are becoming one of the most important agricultural products on a national policy level. Maekawa, subsection chief of the farming section, describe the details of soybean production at JA Tomamae-cho. In recent years, farm land integration has rapidly increased and the cultivating area per farmer has also increased. A farmer who is expanded the scale of his cultivation is highly motivated to plant rice, soybeans, wheat and other agricultural products. The area being cultivated for soybeans was 165 ha in 2006 and grew to 310 ha in 2011. On the other hand, the conventional facilities in the area are old and are not able to meet this expansion in production. Many plans for new beans drying and conditioning facilities were drafted in 2006.

|

| New Bean Drying and Conditioning Facility |

|

| Soiled Bean Cleaner |

Building a New Facility

In conventional conditioning facilities in 1997, beans were placed inside equipment designed for paddy drying and conditioning equipment. There was no equipment designed specifically for beans. The cleaner removes dirt from the surface of the soybean and increases quality. But its capacity is 400 kg per hour and it cannot accommodate the increased soybean production volume. The key themes behind the new facility were “1. Traceability”, “2. Contamination-free” and “3. Commercial-scale conditioning capacity”.

At the time when the plan for this new facility was being developed, JA Tomamae-cho was already aware of Satake’s rack type drying system. The system can dry material in1 ton batches, and JA Tomamae-cho wanted to use it for soybeans. Beans are not contaminated using the system. It is easy to keep track of all products and beans can be dried with zero waste.

|

| Rack Type Drying System |

Finally, they commissioned Satake to design the entire facility to execute the three themes described above. Satake’s unique machines were key factors in the decision. The Soiled Bean Cleaner (BWS20A). The Satake’s original Rinse-Free Rice Production Machine “NTWP” removes bran using tapioca. It has been adapted in this system to remove dirt from the surface of beans. While the plan for the new facility was under consideration, Satake was performing field tests using the test machine in Memuro-cho, Kasaigun, Hokkaido. Akira Maekawa repeatedly checked the performance and consistency of the machine, performing tests using the actual machine and soybeans. Conventional cleaners damage soybean skin, resulting in a reduced shelf life and deteriorating taste. Tapioca removes dirt without harming external appearance quality or taste. The installed soiled bean cleaner’s capacity is 1.5 tons per hour and can operate continuously.

|

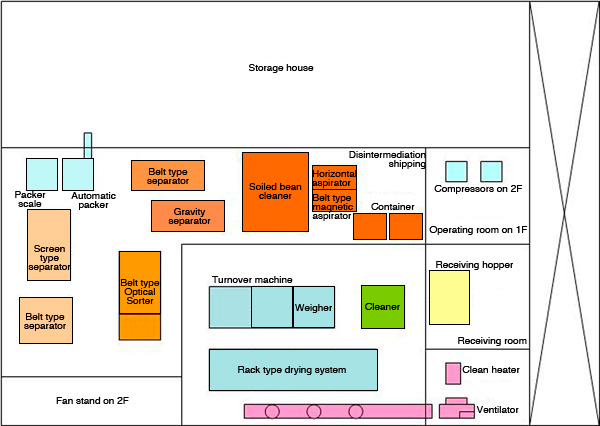

| Diagram of Bean Drying and Conditioning Facility |

Pipeline between Producers and Consumers

Construction of the new beans drying and conditioning facility began on June 20, 2009 and completed on October 16, 2009. The customers of the facility have increased from 156 people in 2009 to 195 people in 2010. The facility excels at product traceability, resulting in smooth information flow between producers and the facility, and between the facility and consumers. In addition, the high drying and conditioning capacity of the facility allows producers to cultivate as many beans as they can without worrying if there is enough capacity to process them. The percentage of grade 1 soybeans produced by the new facility is significantly higher than conventional facilities. Akira Maekawa explained that JA Tomamae-cho’s goal is to establish contracts with all farmers who use the facility to condition and dry their beans. This will allow farmers to enjoy more peace of mind, as they will be assured of a market for their crop.

Outline of Bean Drying and Conditioning Facility at JA Tomamae-cho

Facility name: Bean Drying and Conditioning Facility

Facility name: Bean Drying and Conditioning Facility Business operator: Tomamae-cho of Japan Agricultural Cooperatives

Business operator: Tomamae-cho of Japan Agricultural Cooperatives Facility location: 137-1 Kotanbetsu, Tomamae-cho, Tomamae-gun, Hokkaido

Facility location: 137-1 Kotanbetsu, Tomamae-cho, Tomamae-gun, Hokkaido Design and construction control: Hokuren Agricultural Cooperatives

Design and construction control: Hokuren Agricultural Cooperatives Builder: Satake Corporation

Builder: Satake Corporation Work period: Started on June 20, 2009, completed on October 16, 2009

Work period: Started on June 20, 2009, completed on October 16, 2009 Site area: 4,873.78 m2

Site area: 4,873.78 m2 Building area: 1,068.35 m2

Building area: 1,068.35 m2 Capacity area: 525 ha for soybeans, 195 ha for azuki beans

Capacity area: 525 ha for soybeans, 195 ha for azuki beans Capacity: 1197.7 t for soybeans, 335.4 t for azuki beans

Capacity: 1197.7 t for soybeans, 335.4 t for azuki beans Receiving days: 82 days for soybeans, 23 days for azuki beans

Receiving days: 82 days for soybeans, 23 days for azuki beans Average receiving volume per day: 15 t/day

Average receiving volume per day: 15 t/day

* Please note descriptions in news releases are accurate as of the date of release and may differ from the most up-to-date information.