News Release

Protect Farmers and Region by Establishing Brand and Reducing

July 22, 2013

July 22, 2013

Protect Farmers and Region by Establishing Brand and Reducing

Satellite Drying Facility by JA Nasuno

|

| Tomiike Husking and Quality Control Center |

On July 19th, the Satellite Drying Facility by JA Nasuno completion ceremony was held. It is the first case in Japan where the drying facilitiesand husking facility which also has quality control integrate with each other.

JA Nasuno is located in the northern region of Tochigi prefecture and consists of two cities (Otawara city and Nasushiobara city) and one town (Nasu town).

Total area of the field is 1,319 square kilometers, and 261 is cultivated area, both of which consists 20% of Tochigi Prefecture's area.

Using this vast cultivation area, rice cultivation, horticultural production and livestock production is actively operated providing approx. 39,000 tons of paddy last year. The area is known for producing “Tochigi beef” and raw milknear Nasushiobara city. Under such circumstances, quality compost from dairy husbandry is used for soil production for rice planting. In addition, large temperature changes in a day contributes to improved rice taste.

|

| Tomiike Satellite Center |

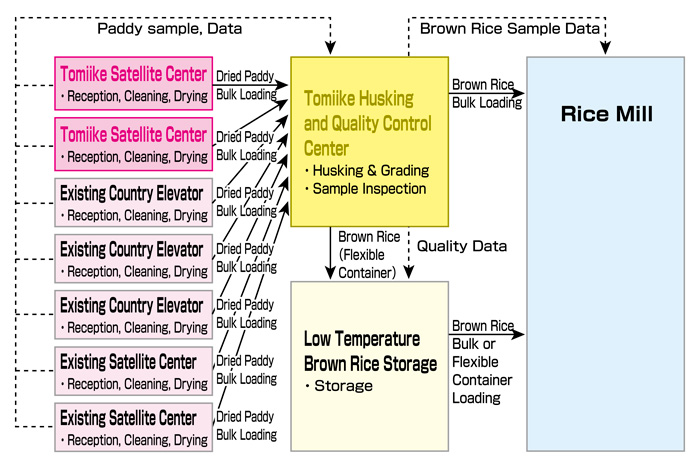

In this JA Nasuno area, new satellite paddy drying facilities are completed. The newly established facilities include Tomiike Husking and Quality Control Center, Tomiike Satellite Center and Yudukami Satellite Center. With Tomiike Husking and Quality Control Center, which primarily operates on paddy husking and grading , in the middle, they established a network of 7 drying facilities (2 newly established and 5 existing). (Network diagram is as shown below.) Each drying facility receives raw paddy from farmers and dries it. Dried paddy is delivered to Tomiike Husking and Quality Control Center for husking and delivery of brown rice. Drying and husking is isolated completely.

This networking concept was built in 1996 when 6 JA in the area integrated and established JA Nasuno, at which time it was only budgeted. Later the project started in 2010.

The project has two purposes. One is to complement manpower. They were seriously suffering from a labor shortage because of decreasing population. Some successors cultivate paddy fields on behalf of aged farmers who have no successors. For them harvesting and drying is big burden in terms of time and economic return. The new facilities are designed to receive all paddy harvested in JA Nasuno area to reduce the burden on farmers.

|

| The latest paddy husker units installed in Tomiike Husking and Quality Control Center |

Another purpose is to improve the quality of rice for branding. Proportion of premium quality of rice that JA Nasuno has produced used to be approx. 95%. Furthermore, they uniquely create a production record to ensure traceability of their product and reduce agricultural chemicals to lower than 11 components, under the “new security rice standard” that they set. Introduction of a warm water seed disinfection device is part of this effort.

The paddy dried by satellite centers is delivered to Tomiike Husking and Quality Control Center after weighing. The Center has 3of the latest 10 inch rubber roll huskers and shell paddy with high efficiency. Consolidation of husking units has reduced maintenance cost. All paddy quality is measured at the reception of satellite facilities and samples are delivered to Tomiike Husking and Quality Control Center along with the inspection data for evaluation. The evaluation is made collectively and paperwork is integrated.

|

| Yudukami Satellite Center |

Brown rice shelled by Tomiike Husking and Quality Control Center can be shipped immediately or be stored in an air conditioned warehouse with a holding capacity of 12,000 tons. They can supply quality rice because they blended all rice and sorted it with the latest full color optical sorters.

Appendix

JA Nasuno Satellite Network Flow

|

Overview of JA Nasuno Satellite Facilities

Business Year : 2011

Primary Contractor : JA Nasuno

Name of Facility : JA Nasuno Satellite Facilities

Builder : Satake Corporation (Plant ? All 3 facilities)

Matsumoto Kensetsu Co., Ltd. (Building ? Tomiike Husking and Quality Control Center, Tomiike Satellie Facility)

Totetsu Kogyo Co., Ltd. (Yudukami Satellite Facility)

Work Period : Tomiike Husking and Quality Control Center, Tomiike Satellite Facility from October 2012 to June 2013.

Yudukami Satellite Facility from October 2012 to March 2013

Application and Capacity : Tomiike Husking and Quality Control Center : Dried Paddy 8,031t, Dried Wheat 3,800t

Tomiike Satellite Facility : Dried Paddy 1,866t (Covered cultivation area 280 ha), Dried Wheat

(Covered cultivation area 100 ha)

Yudukami Satellite Facility : Dried Paddy 920t (Covered cultivation Area 140ha)

Total Floor Area: Tomiike Husking and Quality Control Center : 1,394.52m2

Tomiike Satellite Facility : 806.92m2

Yudukami Satellite Facility : 91.36m2

Total Land Area : Tomiike Husking and Quality Control Center and Tomiike Satellite Facility : 28,389.30m2

Yudukami Satellite Facility : 5,440.22m2

Receiving Capacity : Tomiike Husking and Quality Control Center : Dried Paddy 97tons/day, Dried Wheat 148tons/day

Tomiike Satellite Facility : Dried Paddy 95tons/day, Dried Wheat 51tons/day

Yudukami Satellite Facility : Dried Paddy 55tons/day

* Please note descriptions in news releases are accurate as of the date of release and may differ from the most up-to-date information.