News Release

High Capacity Continuous Type “Bean Cleaner” Released

May 26, 2014

May 26, 2014

High Capacity Continuous Type “Bean Cleaner” Released

For higher quality product with less time, labor and cost

Satake launches “Bean Cleaner”, a machine that removes dust and dirt from the surface of beans, on June 1st.

It is a high capacity continuous type machine suitable for bean drying and processing facilities

|

Bean Cleaner |

There are situations where dust and dirt adheres to the bean surface from harvesting and berry dropping process. Bean processers used to remove this dust and dirt after drying. Typical machines used for bean cleaning are small with a capacity less than 1 ton per hour. They are installed off-line, separate from the main processing line, and require a regular operator in the most cases.

The new bean cleaner has a 2 tons per hour capacity and can be installed in the processing line. It does not require a regular operator lowering cost of processing. The cleaner uses edible tapioca pearls for polishing. Because tapioca pearls can repeatedly be used unlike corn cobs used in the typical bean cleaning machines, the cost of the polishing agent can be reduced by 1/6.

Appendix

Bean Cleaner BWS20A

1. Features

- (1) Labor Saving

- It can be installed in the main processing line and can be operated continuously, without

requiring a regular operator. - (2) Polishing Agent Cost Reduction

- Reusable tapioca is used as the polishing agent. The cost of polishing agent can be

saved by 1/6 compared to conventional cleaning machines that use disposable corn cobs. - (3) Better product Appearance

- The new Bean Cleaner processes beans in two stages: dry process and wet process.

It cleans the bean surface efficiently with very little water.

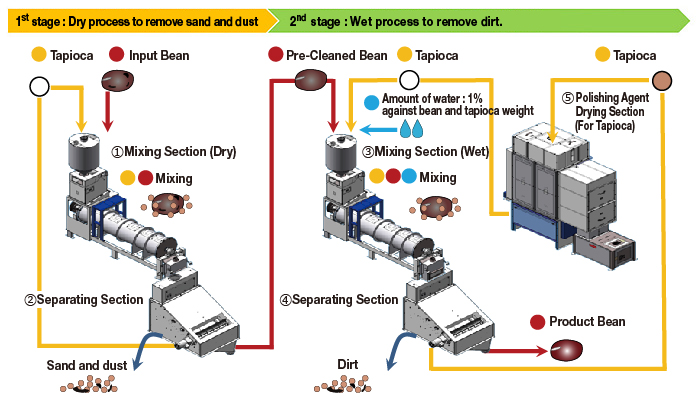

2. Process Flow

1st stage : Beans and tapioca is mixed to remove dust on the bean surface.

2nd stage : Beans, tapioca and very little water is mixed to remove dirt adhered to its surface.

3. Specifications

| Model | BWS20A | |

|---|---|---|

Applications ※1 | Variety | Soybean, Azuki Bean, Tebo Bean |

| Moisture Content (weight basis) | 15% and lower | |

| Processing Capacity | 1.6~2.0 t/h | |

| Power Source | 3 phase 200V (50/60Hz) | |

| Required Power | 19.9kW | |

| Required Water | Tap water : 16~20L/h | |

| Amount of tapioca to add | 3.2~4.0t/h | |

| Amount of fuel Required | Kerosene 3~4L/h | |

| Required Suction ※2 | 55m3/min and over | |

※1 Materials should not contain branch and cod

※2 Static pressure : 2.2kPa

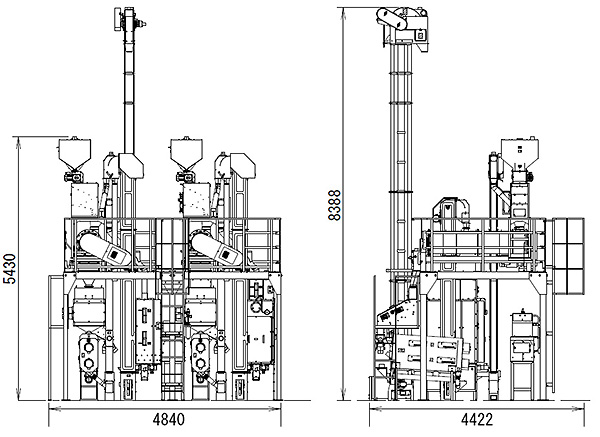

3. Dimensions (unit : mm)

* Please note descriptions in news releases are accurate as of the date of release and may differ from the most up-to-date information.