News Release

Satake Develops Packed Rice Production System (Retort)

July 31, 2009

July 31, 2009

Satake Develops Packed Rice Production System (Retort)

Produces Firm, Lustrous and Tasty Packed Rice

Packed Rice Production System (Retort)

On August 1, 2009, Satake began sales of the Packed Rice Production System (Retort). This system uses pressurized microwave heating technology to produce tasty, convenient packed rice.

Conventional packed rice can be classified as either aseptic rice or retort rice, depending on the processing method used. Aseptic rice uses simpler processing equipment but needs pH adjusters to suppress bacterial growth. As a result, cooked rice retains the odor of the pH adjuster, and using too much pH adjuster can cause the rice to deteriorate. Retort rice uses pressure and heat to ensure product safety and does not need pH adjusters. However, the retort sterilization procedure requires that the rice be kept at a high temperature for a long period of time, resulting in squashed rice with poor texture.

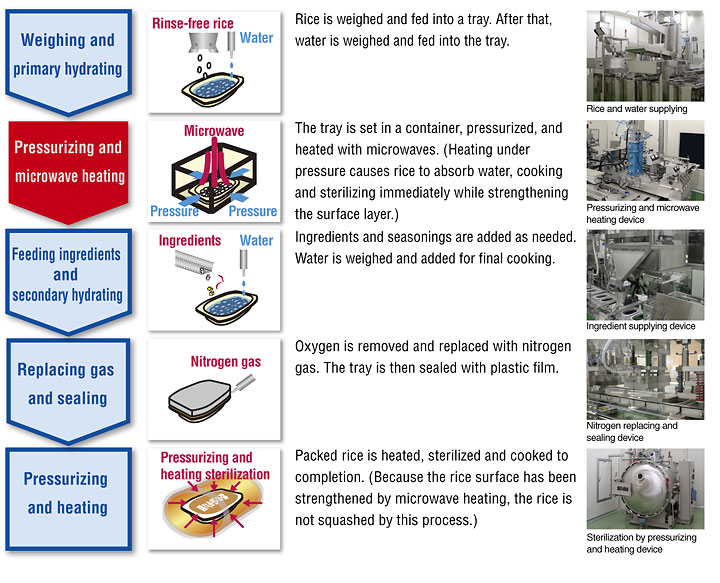

Satake's new Packed Rice Production System (Retort), however, uses pressurized microwave heating before the final cooking process. Pressurized microwave heating causes rice to absorb water, rapidly cooking and sterilizing it while strengthening the grain surface to protect against the high temperature and pressure of the final process. The result is perfectly shaped, lustrous rice with a firm exterior and sticky interior.

Satake has installed a test plant with a capacity of 300 packs per hour in the showroom of its Hiroshima head office. Customers can request trial production runs of packed rice and assess the final product before installing the system. Satake also sells its own brand of packed rice known as “Rakumeshi” directly from its online shop so that rice lovers everywhere can taste the advantages of the new producing process.

Reference

Features

Pressuring and Microwave Heating Device

- Produces firm, lustrous, tasty rice.

- Can produce packed rice with added ingredients or rice-derived functional components.

- Can produce a wide variety of products in small quantities.

- Substantially increases rice volume during cooking.

- Odor-free

- Production process is highly efficient and environmentally friendly.

Comparison with Conventional Method

| Satake Packed Rice | Aseptic Rice | Conventional Retort Rice | |

|---|---|---|---|

| Sterilization | Sterilization by pressurized microwave heating and pressurized steam heating (No pH adjuster) | PH adjuster (acid) suppresses bacteria growth. | Sterilization by pressurized steam (No pH adjuster) |

| Taste | A hard layer forms on the rice surface, producing lustrous, firm and tasty rice. | Acidic taste and odor from pH adjuster adversely affect rice taste. | Processing at high temperatures for a long time squashes. Texture is bad. |

Producing Process

* Please note descriptions in news releases are accurate as of the date of release and may differ from the most up-to-date information.