News Release

Satake Launches Pellet Sorter II

June 19, 2025

June 19, 2025

Satake Launches Pellet Sorter II

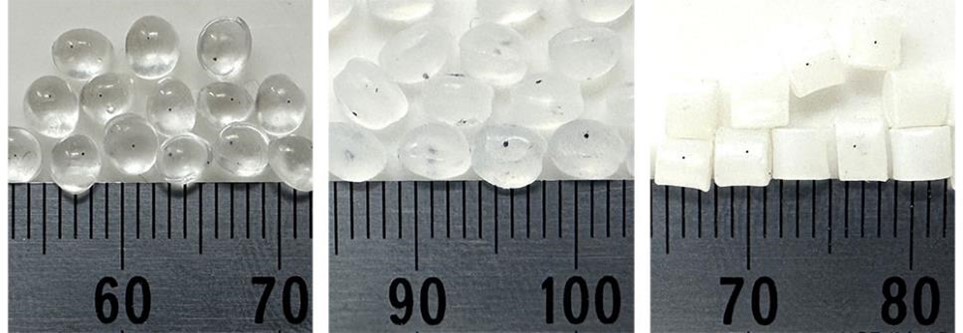

Precise Sorting of 0.1mm Speck-damaged Plastic Pellets

|

|

Pellet Sorter II |

Hiroshima, Japan; June 19, 2025 - Satake launched an optical sorter exclusively developed for plastic pellets, Pellet Sorter II.

Pellet Sorter II is a specialized optical sorter to remove defective products such as speck damage and discolorations mixed in plastic pellet raw materials, with a high throughput of up to 3.0t/h.

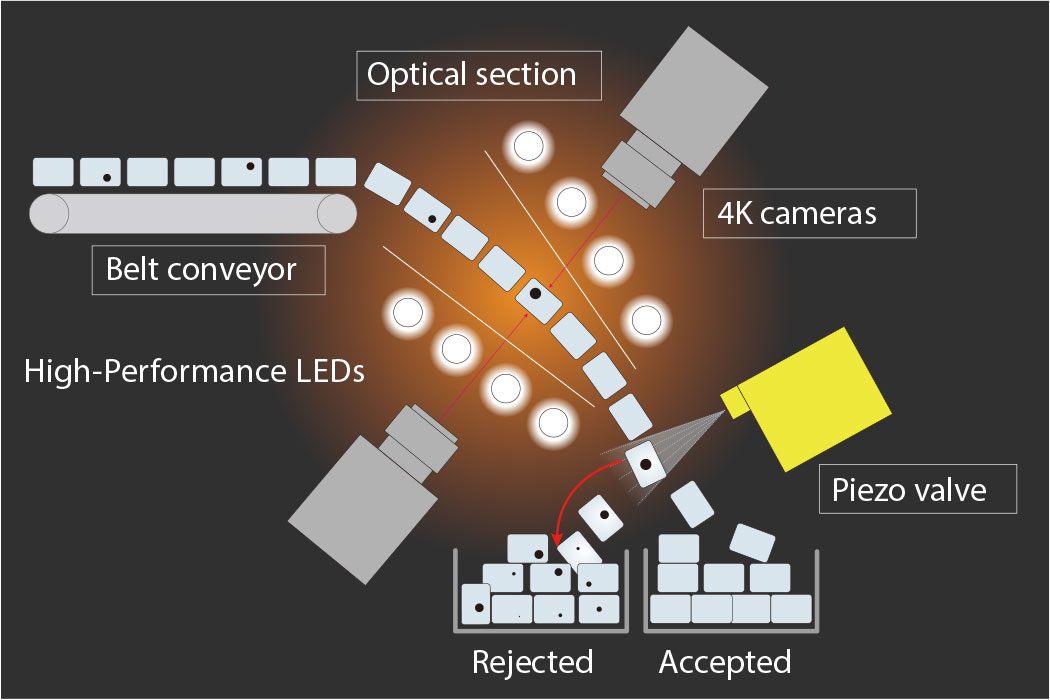

Fed by a 600mm wide belt conveyor, product is scanned by front and rear 4K high-definition cameras. Using Satake Intelligent Software, accept and reject products are instantly identified and reject products are efficiently removed by the high-speed Piezo ejector valves.

In 2009, Satake developed the first Pellet Sorter, an optical sorter capable of sorting plastic pellets, which achieved results not previously possible within the industry. Committed to continuous development of new technology, Satake has not rested and has been working on the development of a new optical sorter with the aim of further improving the defective product sorting ratio.

The new Pellet Sorter II was redesigned to use high intensity LED lighting and now has the ability to sort transparent or opaque pellets with a single unit.

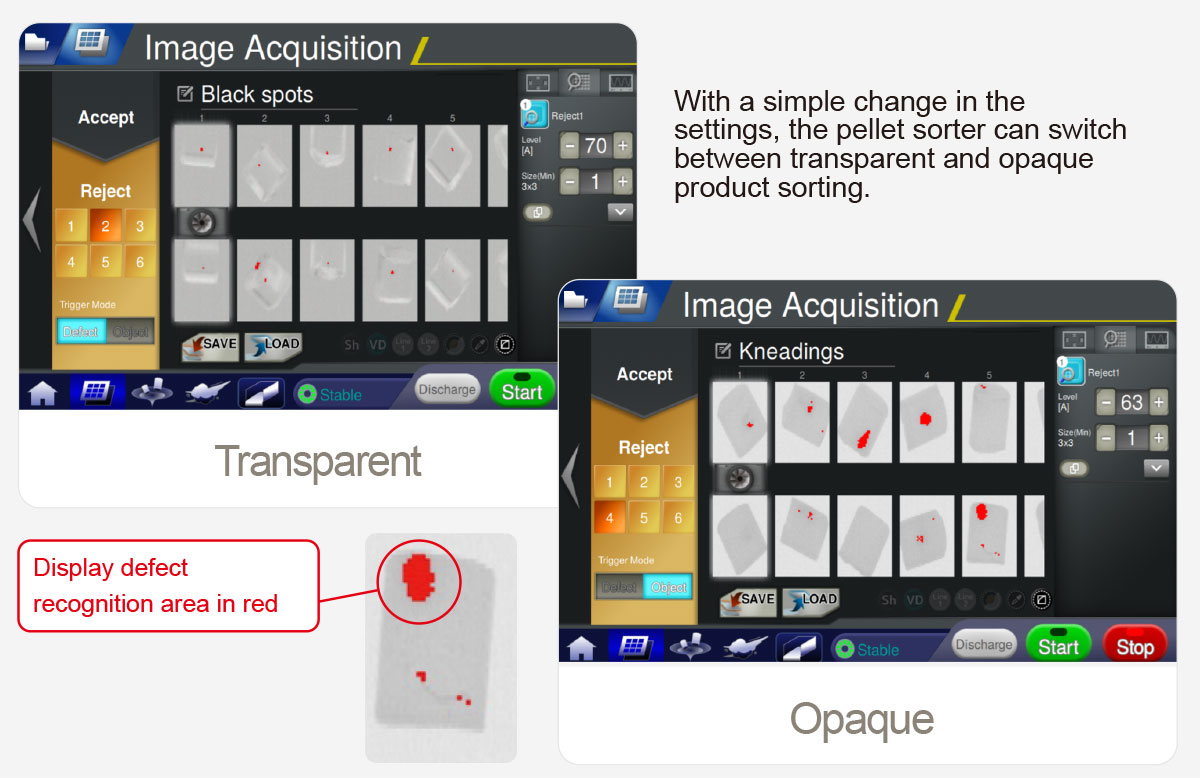

In addition, the all new 4k cameras, combined with advanced Japanese designed high-speed signal processors and Satake Intelligent Software give the high resolution to achieve precision targeted separation of discolored and defective pellets and can detect 0.1mm speck damage. The adoption of patented Piezo valves enables removal of defective pellets with pinpoint accuracy to increase the purity of the plastic pellets while minimizing product loss.

-- -- -- -END- -- -- --

*Please note descriptions in news releases are accurate as of the date of release and may differ from the most up-to-date information.

Appendix

【About Pellet Sorter II】

■Structure

■Features

1.High-precision detection of speck damage (above 0.1mm)

2.Transparent and opaque pellet sorting with a single unit

With a simple change in the settings, the pellet sorter can switch between transparent and opaque product sorting.

3. High intensity LED lighting is used in the optical section

High-performance, long-life LED for consistent precision lighting

4. Piezo ejector valves.

Newly designed Piezo ejector valves:

・ 1.7 times faster response time than solenoid valve ejectors, minimizing the loss of accept product.

・ Service life 3 x longer than solenoid valve ejectors

・ Reduced air and power consumption

5. Easy cleaning design

・ Stainless steel body

・ Removable parts for easy cleaning, reducing the risk of cross contamination.

■Specification

|

Model |

PCS600BWT |

|

|

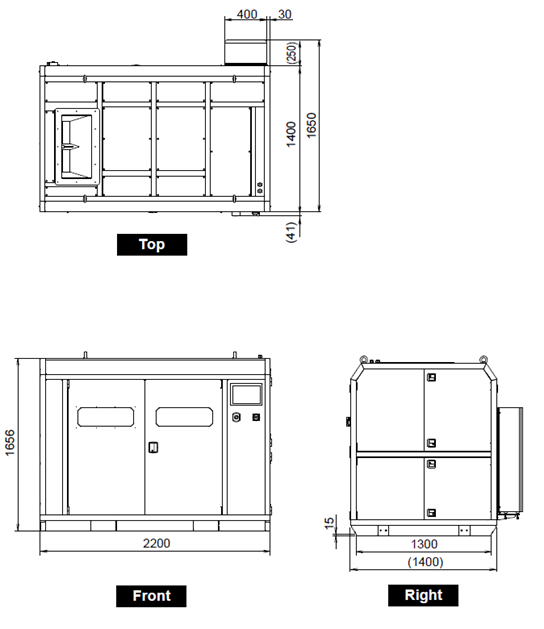

Dimensions (mm) [Width×Depth×Height] |

2,200 × 1,650 × 1,656 |

|

|

Machine weight (kg) |

1,100 |

|

|

Power supply (V) |

Single phase AC 200 ~ 240V 50Hz/60Hz |

|

|

Required power (kW) |

2.3 (max) |

|

|

Required air volume (NL/min) |

500 ~ 750 (compressor 5 ~ 7.5kW) |

|

|

Main applications |

Transparent and opaque plastic pellets |

|

|

Capacity (t/h) |

0.1 ~ 3.0 |

|

■Dimensions(mm)

-- -- -- -END- -- -- --