Excellent sorting performance for foreign materials

Equipped with the “SLASH” optical sorting machine, a near-infrared camera with a new wavelength and a new LED light source improve sorting accuracy, while the “Piezo Valve” has reduced the number of good products that are removed along with defective products.

Available for small-lot production

While processing a maximum of 500 kg/h, it is possible to mill rice from 10 kg.

Residual-less structure

Equipped with a residual rice removal function to eliminate contamination problems.

Equipped with optical sorter SLASH

Two wavelengths, two near-infrared cameras

Since transparent or same-colored foreign materials cannot be detected in the visible light range of wavelengths by a full-color camera, near-infrared (NIR) light is used to sort foreign materials by their spectral characteristics (transmission or reflection).

SLASH is equipped with a near-infrared camera with two different wavelengths to improve the accuracy of foreign object sorting, such as silica gel and transparent resin.

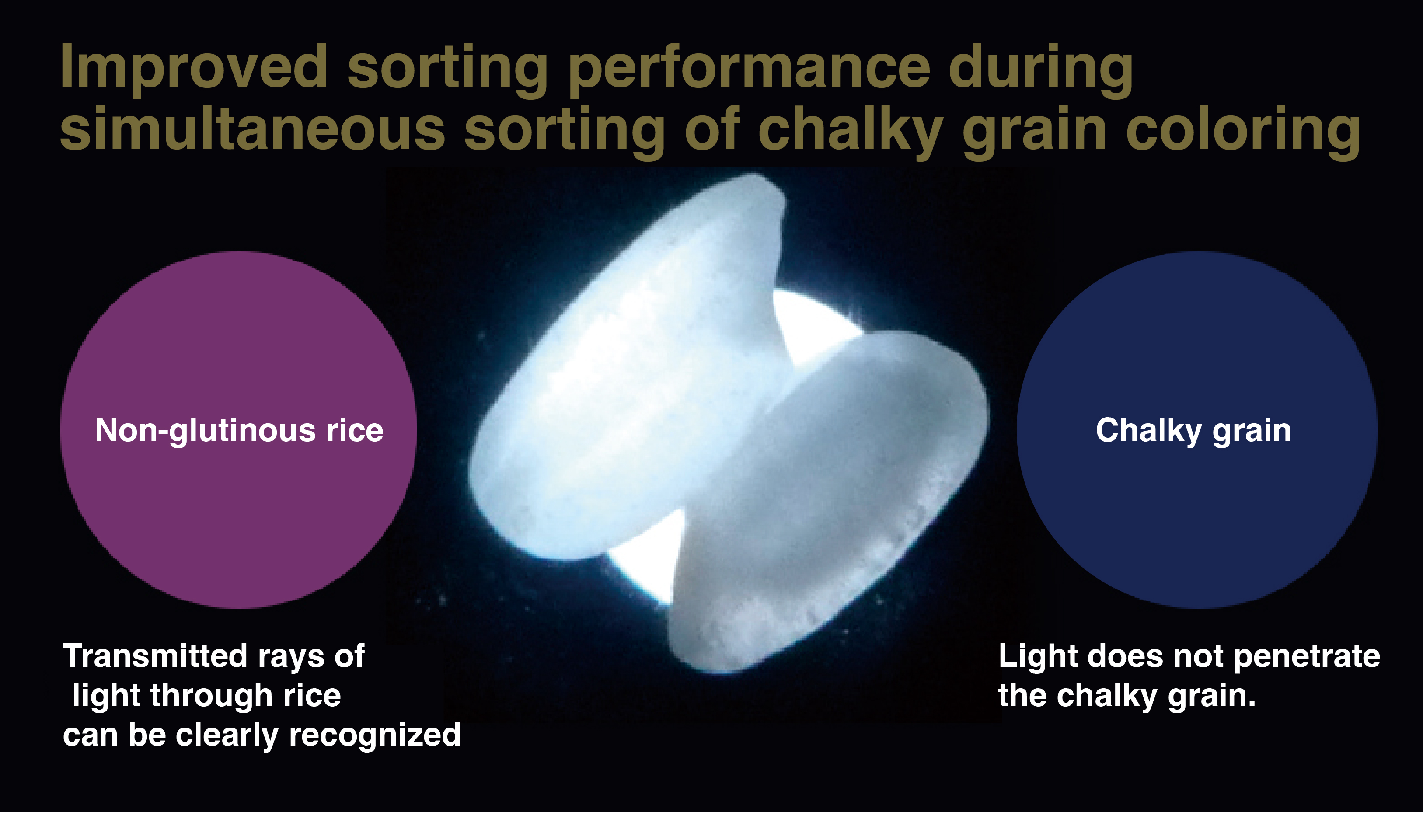

Improved performance of chalky grain sorting

The use of bright LEDs instead of CCFLs (cold cathode fluorescent lamps) as the light source has improved the performance of sorting chalky grain without reducing the sorting capacity for colored grains.

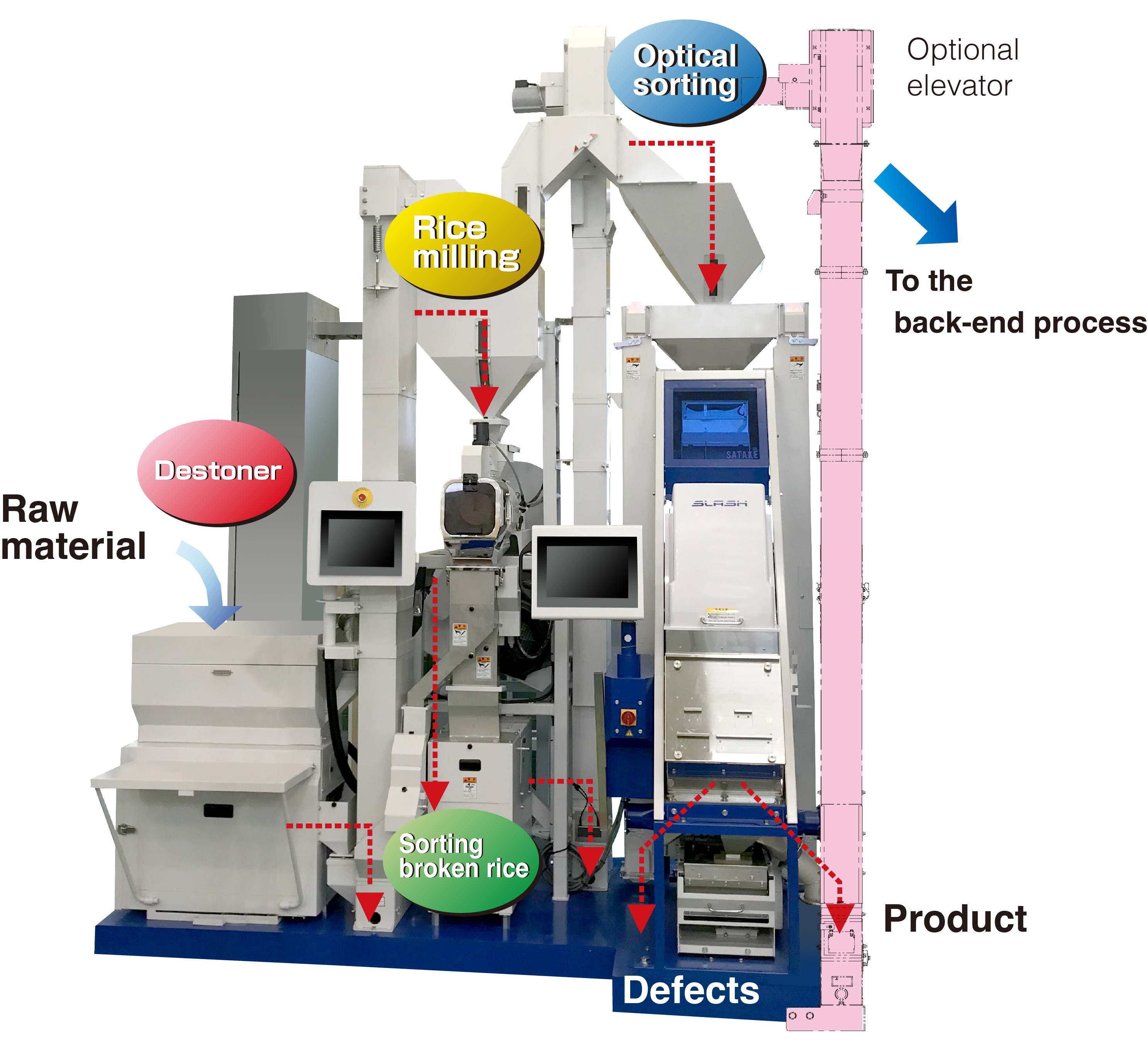

Raw material flow